Quality Control

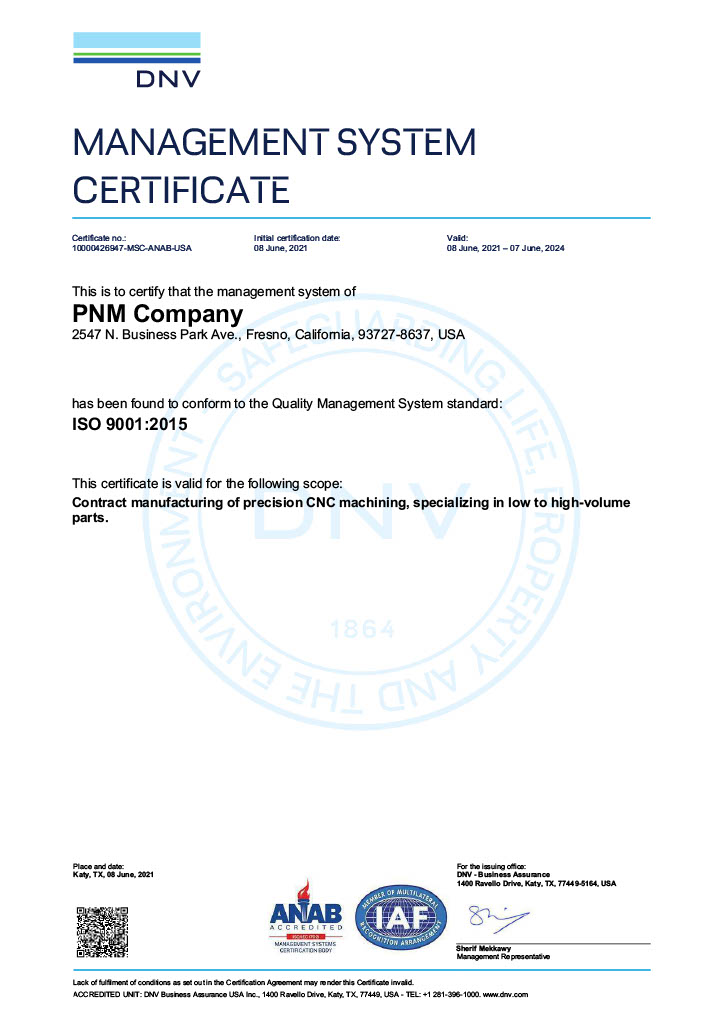

ISO 9001:2015 Certified

Certification Number 10000426947-MSC.ANAB-USA

Commitment to Quality

Our systems and processes were created to meet rigid customer demands. We only use consistent suppliers and approved sources that know the needs of our customers. We apply the latest technologies, have documented-controlled processes and highly experienced quality technicians.

Quality Policy

PNM will provide precision machining and Factory Added Throughput Savings (FATS) that helps our clients meet or exceed their goals. We commit to maintaining a company that continually seeks out and implements improvements all year long. We will accomplish this through the best people, and using advanced technologies which reduce processing time, lower costs and drive high quality.

We further commit to the ongoing training of our employees, using the best technologies and equipment, creating an environment of “continuous improvement”, and working toward achieving our quality objectives. We will comply with the goals of ISO 9001, as well as all applicable government and industry requirements.

OUR QUALITY OBJECTIVES

We will follow our quality policy in pursuit of our quality objectives:

- Achieve High Levels of Customer Satisfaction

- Maintain A Competitive On-Time Delivery Position to Our Customers

- Maintain Good Quality Levels

- Manage our Supplier’s On-Time Delivery to PNM

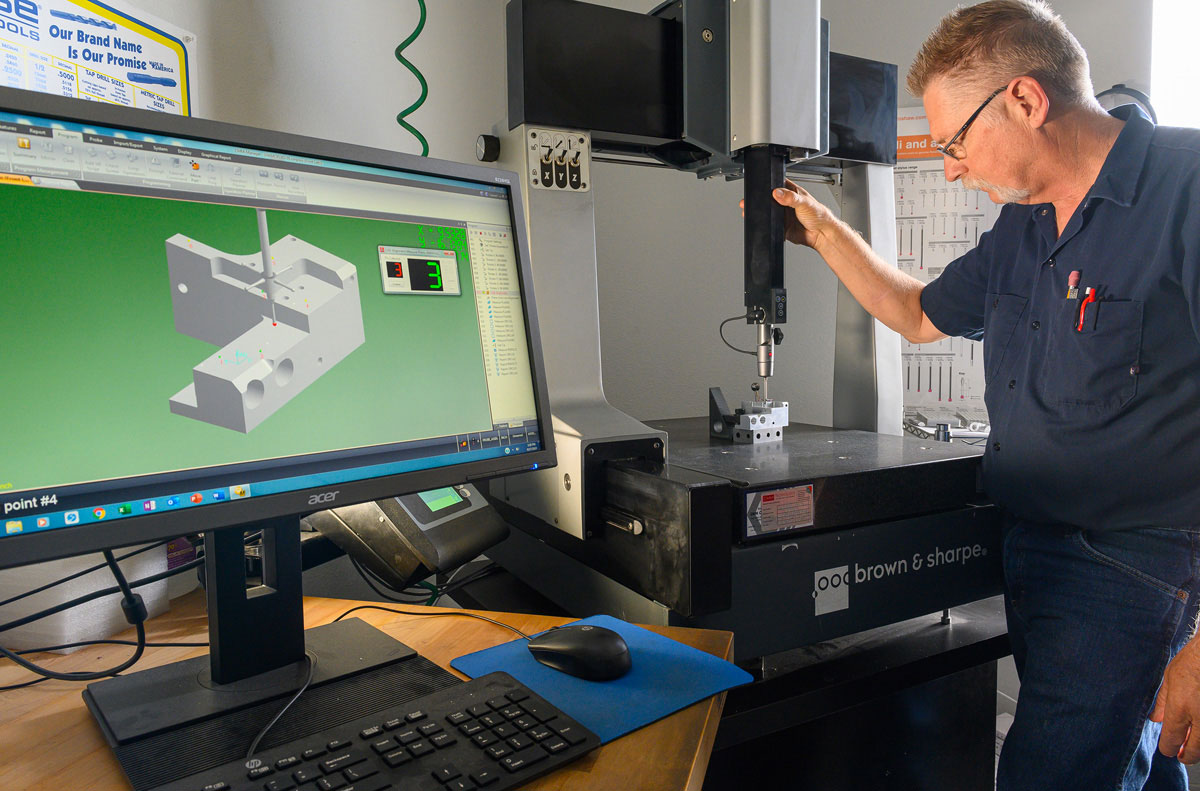

Quality Facility

PNM uses a state of the art facility to ensure all production is manufactured with the highest degree of quality. We draw on the latest technology when it comes to excellence in part production. Our quality department works within the structure of our quality system to verify that customer requirements are met. Our engineering and quality staff provide the detailed, comprehensive inspection and test reports that sustain your confidence in our quality performance.

Inspection Equipment

MITUTOYA BH 506 Coordinate measuring machine w/GEOPAK software

- Automatic self-alignment

- Zero Preset

- Point Center , Location, Roundness and Diameter

- 3-D angle/plane angle

- Cartesian/polar conversion

- Diametrical true position

- RENISHAW MIP probe

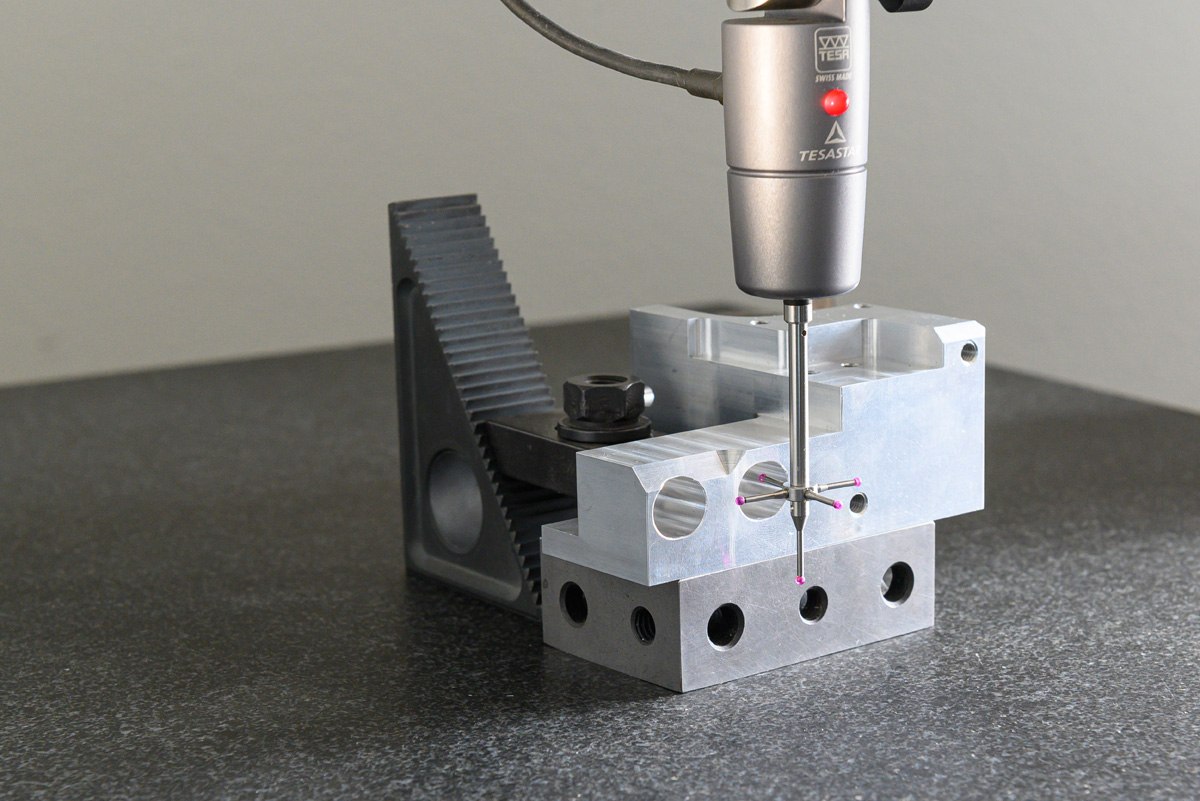

BROWN AND SHARP GAGE 2000 COORDINATE MEASURING MACHINE

- Reflex software

- Point Center , Location, Roundness and Diameter

- 3-D angle/plane angle

- Cartesian/polar conversion

- Diametrical true position

- TESASTAR probe

KEYENCE XM SERIES PORTABLE CMM

- Interactive Augmented Reality Guidance

- Automatic Data Management

- Complex Geometry Guidance

STARRETT 24″ X 36″ CRYSTAL PINK SURFACE PLATE

MASTER GAGE BLOCKS AND GAGE PINS

REFERENCE GAGE BLOCKS AND REFERENCE GAGE PINS

THREAD GAGES (PLUG & RING)

30X MICROSCOPE

ALINA DIAVITE PROFILOMETER

MITUTOYO HOLTEST MICROMETERS WITH RING GAGES

INTERNAL BORE GAGE TO 8″

DIAL CALIPERS TO 8″

VERNIER CALIPERS TO 36″

MICROMETERS TO 12″

MULTIPLE DIAL AND TEST INDICATORS .0001″ INCREMENT

SINE BARS

ANGLE PLATES

V-BLOCKS

UNIVERSAL BEVEL PROTRACTOR

VARIOUS MICROMETERS (INSIDE, OUTSIDE, FLANGES, HOLE CENTERS, GROVES, DEPTH AND THREADED)

All inspection equipment is calibrated in accordance with MIL-C-45662

In addition to the Quality equipment detailed above, we maintain a large assortment of specialty production and inspection tooling.