Our Facility

PNM Facility Equipment List

Our reputation for high quality machined components has solidified our relationships with companies seeking the highest level of expertise.

We produce components for numerous medical device, automotive, aerospace, food processing, lighting and technology companies as well as departments of the government that are in products spanning the globe.

We could not do this without a state-of-the-art manufacturing facility comprised of cutting edge technologies.

Primary Manufacturing Equipment & Accessories

(1) Haas VF2SSYT

with Fanuc M10 robotic cell (Trinity Automation). Cell has 56 8” x 12” pallets designed to run lights out

FIFTY SIX PALLETS IN USE 24/7

(3) 6 Pallet 400mm Kiwa Horizontals

THREE IN USE 24/7 18 PALLETS

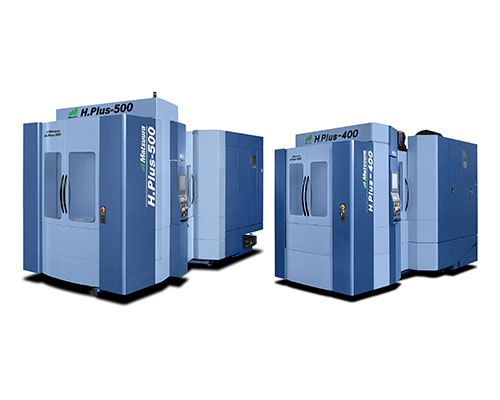

(2) Matsuura H-Plus 300 Horizontals

with 36 linear pallet system

TWO IN USE 24/7 36 PALLETS

(1) Matsuura H-Plus 300 horizontal

with 26 linear pallet system

TWENTY-SIX LINEAR PALLETS IN USE 24/7

(1) Doosan Horizontal

with a 12 pallet linear pallet system

TWELVE PALLETS IN USE 24/7

(10) Haas VF2 SS

vertical machining centers (4 Midaco pallet shuttles)

TEN HAAS VF2S IN USE 24/7

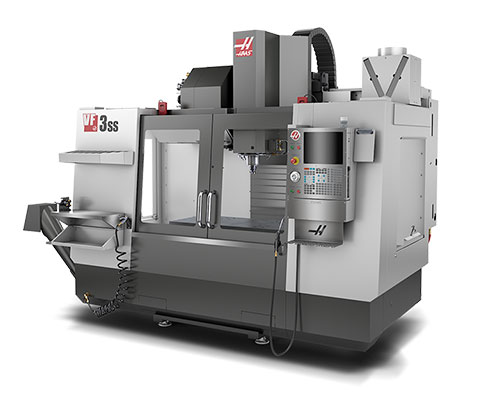

(2) Haas VF3 SS

Vertical Machining Centers

TWO HAAS VF3s IN USE 24/7

(1) Citizen L632

Screw Machine

CITIZEN SCREW MACHINE IN USE 24/7

(1) Ganesh Cyclone 32cs 7

Turning Center

GANESH TURNING CENTER IN USE 24/7

(2) Mori Seki SL204 SMC

with bar loaders

TWO MORI SEKI LATHES IN USE 24/7

(1) Doosan Lynx 220L

Turning Center

DOOSAN TURNING CENTER IN USE 24/7

(1) Doosan 2600Y Y Axis

Turning Center

DOOSAN TURNING CENTER IN USE 24/7

(1) Hwacheon C1-YSMC

Turning Center

Hwacheon Turning Center In Use 24/7

(1) Mazak Nexus 100

Turning Center

MAZAK TURNING CENTER IN USE 24/7

(1) Haas TL1

Tool Room Lathe

IN USE 24/7

(1) Haas ST10Y Y Axis

Turning Center

Haas Turning Center in Use 24/7

Quality Control Equipment

(1) Brown and Sharpe CMM

with programmable software

(1) Keyence XM SERIES

Portable CMM

(1) 24″ X 36″ Surface Plate

Inspection Table

Contact us today to see how the team at PNM CNC Machining can help complete your project, improve your workflow, and maximize your satisfaction as a client.

Copyright © 2019 PNM Company | All Rights Reserved